A bucket elevator, also called a grain leg, is a mechanism for hauling bulk materials (most often grain or fertilizer) vertically.

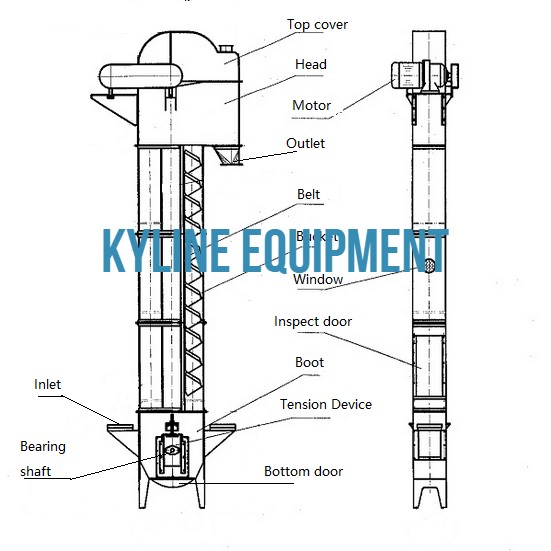

The structure of grain leg:

- Bucket: contain the material, usually bolted onto belt.

- Belt: to carry and move buckets

- Trunking: Hold belt and buckets

- Head: drive pulley, chain or belt and motor

- Boot: pulley, tension device and bottom door

Advantages of grain legs:

- Can handle all grains

- Wide range of capacities, can be huge

- Less power consumption

- Less damage to grains

- High hoisting height

- Work in all weather conditions

- Long service life

- Occupy relatively small area

- Quiet

- Relatively free of maintenance

- Require little labor to operate

The primary disadvantage of bucket elevators is the high purchase costs. Kylin provides high quality bucket elevators with very competitive prices. Here are our models.

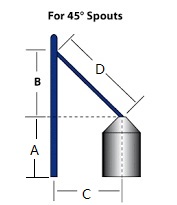

How to calculate the bucket elevator height you need?

The height of the bucket elevator is determined by the key factor: down spouting angle. For most cases 45 degree is the minimum angle for a grain leg to work at full speed. If you load very light material or even wet material you might need steeper spout.

To get 45 degree spout, two measurements are needed: the height of the grain bin – A and distance from center of the grain bin to the grain leg – C.

The discharge height is A+B.

B equals to C.

The spout length D = 1.414 x C.

If you have more than one bin and have a distributor then the height should be discharge of the distributor.

The total height is a bit more than the about calculation counting the height about the discharge point. 4-6 feet should be added to get the total height.

A shorter leg won’t save a lot of money, but you might have to slow down and have the risk of plugging spouting. It’s pricey to add extra trunks, reinstall belt and buckets, reinstall spout, run guy wires…

You can go even higher if planning to set up another bin beside in the future. The extra height will give more flexibility.

How big is the motor?

There’s a simple formula to decide the motor horsepower for lifting grains:

HP = H*C/33,000*1.2

H: Height of discharge in ft, C: Capacity, bushel per hour

1.2 is the safety factor

For example: discharge height 60ft, 1000bph, the motor is:

60*1000/33,000*1.2=2.18 hp

Bucket elevator installation

To install a grain leg is not very difficulty, just need some common sense.

What needed: Solid floor or concrete slab, bucket elevator parts, crane, some tools.

Start from bottom to top.

- Mount the boot to the floor. Make sure the boot is level.

- Install trunking. bolt them one by one. Don’t try to bolt all trunks on ground and lift them with the crane. The long trunks might be bent.

- Install the head. Install the motor. Bolt the head to the top trunk section.

- Install ladders and platform, if you have.

- Run guy wires.

- Install the belt.

- Take off the inspection cover at the boot, so belt can be touched through the window.

- Adjust the tension device at boot to top position. It’s easier to install belt.

- Take off the head cover.

- On the platform or use a manlift, run the belt over the head pulley, down through the trunk and go back under the bottom pulley.

- overlap the both ends of the belt. Use a special device to tighten the belt.

- Drill holes in belt and bolt ends together.

- Install the buckets:

- bolt the buckets on the belt through the inspection window at boot

- pull the belt down and install buckets one by one.

- Connect the wire: Connect power to the motor.

- Start and adjust:

- tighten the belt by pushing down the tension device.

- Turn on and adjust the tension screw to make the belt at the center.